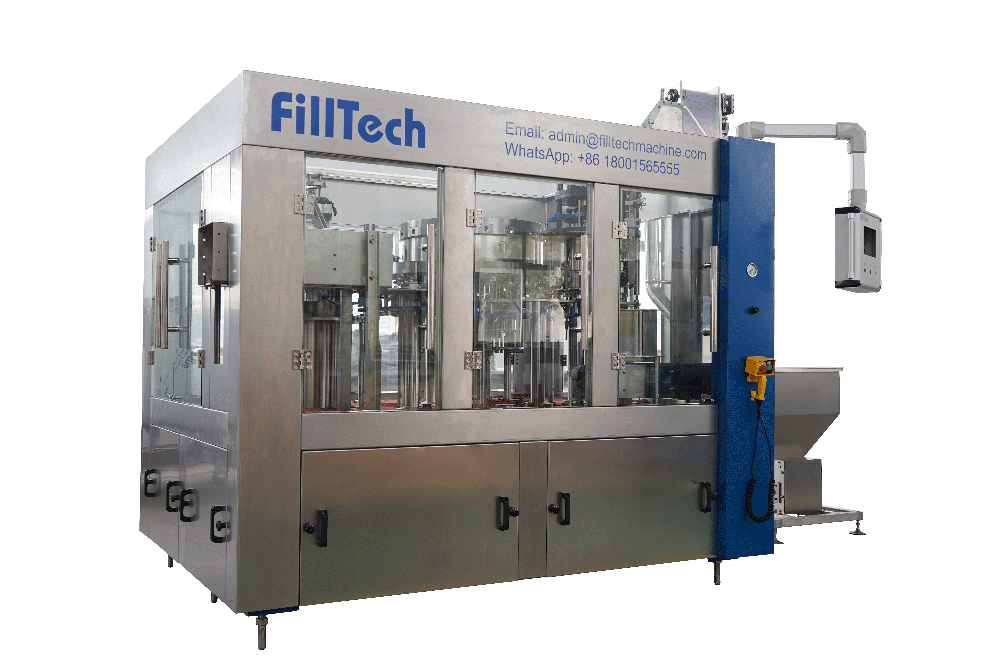

The beverage industry is highly competitive, and the need to produce high-quality products within a short time is equally important. In response to this need, manufacturers have developed state-of-the-art machines, such as the 20,000BPH Carbonated Soft Drink Filling Machine, to streamline the beverage filling process. This article will explore the features, benefits, and applications of this machine in-depth.

Features of the 20,000BPH Carbonated Soft Drink Filling Machine

1. Three-in-one Design

The DCGF50-50-15 washing, filling capping 3in1 machine is designed with three functions of bottle rinsing, filling, and capping in one body of the machine. The machine is fully automatic, which ensures that the beverage filling process is efficient and takes less time.

2. Polyester and Plastics Bottle Compatibility

The machine is designed for filling carbonated beverages in bottles made of polyester and plastics. This feature enhances flexibility, as the machine can fill different bottle sizes.

3. Handle for Adjustment

The machine is fitted with a handle that can be turned freely to adjust the machine and fill different types of bottles. This feature enables the machine to fill different bottle sizes and shapes, which makes it versatile.

4. Equal Pressure Filling Operations

The machine is designed with equal pressure filling operations, which ensure that the bottles are filled to the required amount. This feature eliminates spillage and guarantees consistent product quality.

Applications of the 20,000BPH Carbonated Soft Drink Filling Machine

The 20,000BPH Carbonated Soft Drink Filling Machine is mainly used in the beverage industry for filling carbonated drinks in plastic and polyester bottles. The machine is suitable for production lines with high throughput requirements and guarantees efficient and fast filling of carbonated drinks.

Benefits of the 20,000BPH Carbonated Soft Drink Filling Machine

1. High Productivity

The machine is designed to fill 20,000 bottles per hour, which is a significant benefit for beverage manufacturers who require fast production lines. The high output of the machine is attributed to the equal pressure filling operations, which guarantee consistent beverage quality.

2. Consistent Product Quality

The seamless design of the machine, coupled with the equal pressure filling operation, ensures that the beverage is filled to the required level, eliminating spillage. This feature guarantees product quality consistency, which is essential for customer satisfaction.

3. Versatility

The machine is designed to fill various bottle sizes and shapes, making it versatile. Beverage manufacturers can use the machine to fill different types of carbonated drinks in polyester and plastic bottles.

4. Efficient Beverage Filling

The fully automated machine with three functions in one body ensures that the beverage filling process is efficient and takes less time. This feature is a significant benefit for manufacturers who require fast production lines.

Conclusion

The 20,000BPH Carbonated Soft Drink Filling Machine is a high-end machine designed for ascertained Beverage manufacturers seeking efficient and fast production lines. The machine's seamless design, coupled with the equal pressure filling operation, guarantees consistent product quality, while the handle for adjustment ensures versatility. The machine is highly efficient, and manufacturers can fill different types of carbonated drinks in polyester and plastic bottles. Overall, the 20,000BPH Carbonated Soft Drink Filling Machine offers immense benefits to the beverage industry.